Table of contents:

Is your domestic machine struggling with thick fabrics or large volumes? It’s time for you to switch to a industrial sewing machine if you want to boost your creativity without sacrificing quality.

In this article, we break down for you the models that hold up (Juki, Janome, Elna), the pitfalls to avoid, and tips to combine production speed with controlled budget. You will finally know which gem to choose to transform your workshop into a highly efficient sewing factory.

Understand your industrial sewing needs

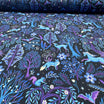

To succeed in industrial sewing, it is essential to precisely identify your needs: types of materials (lightweight, thick, technical textiles) and production volumes (small batches or high rates). These criteria guide the choice of equipment, whether it is a suitable industrial sewing machine, a flatbed stitcher, an overlocker, a free-arm machine, or even an automated model. A good match between your requirements and the equipment ensures productivity, quality, and durability.

Identify materials and production volumes

Rigid denim or thick leather require specialized needles and powerful motors. Conversely, soft jersey demands an industrial overlocker for clean finishes. Each fabric dictates its rules, and only a well-chosen industrial sewing machine can guarantee smooth work adapted to these requirements.

Need to produce 500 visits per week? A 5,000 stitches/minute machine becomes your ally. But beware: high speed requires precise thread tension and a reinforced feed system to avoid repeated jams. The pace imposes its technical constraints.

Still hesitating to take the leap to an industrial or semi-industrial machine like the JUKI TL-2200QVP Mini? Here are the unmistakable signs:

- Intensive production with more than 1000 pieces monthly: your domestic machine is suffocating

- Frequent needle breaks on thick leather or denim: need for real mechanical power

- Deformation of seams on stretch fabrics: the industrial overlocker becomes essential

- Constant thread tension adjustments: professional systems guarantee stability

- Daily sewing hours over 4h: only an industrial machine can go the distance

If 3 of these points resonate with your daily life, an upgrade is necessary!

The different types of machines available

The flatbed sewing machine remains the reliable choice for workshops. Perfect for assembling shirts or curtains, it swallows meters of straight stitching without flinching. Its strong point? Unmatched versatility.

|

Comparison of types of industrial sewing machines and their key features |

|

|

Type of machine |

Main use |

|

Flatbed sewing machine |

Standard garments, fine to medium fabrics |

|

Industrial overlocker |

Clean finishes (jersey, knit) |

|

Triple feed |

Leather, thick jeans, multiple layers |

|

Overlocker |

Elastic hems (technical garments) |

For demanding technical fabrics like thick leather, triple feed works wonders. The feed dog, presser foot, and needle synchronizedly pass through multiple layers without deviation. It’s the secret weapon of professional leatherworkers, provided it is paired with an industrial sewing machine designed for precision and power.

Take a look in our online store to discover the best industrial machines of the moment. You can contact us at any time to order or get any information about our products and services.

Important criteria for an informed choice

Before starting an industrial sewing project, it is essential to clearly identify your needs. This includes the type of materials to work with, the expected production volumes, as well as the choice of a suitable industrial sewing machine. Each element directly affects performance, quality, and profitability of production. Here are the basics to make the right choices from the start.

Power vs precision: the keys to performance

An oversized motor consumes unnecessarily, while an underpowered model overheats. For an industrial sewing machine, you need to find the sweet spot between endurance and agility, depending on your use and the materials worked.

Thread tension makes all the difference between a professional stitch and a rough DIY job. Dynamic spring systems maintain perfect consistency even at 5,000 stitches/min. You will be assured of flawless results on all thicknesses.

Test your future machine like a pro with these essential checks:

- Stability of the stitch over 10 layers of denim: reveals the true driving power

- Smoothness of tight curves: demonstrates the precision of guidance

- Relative silence at 4500 rpm: a sign of well-oiled mechanics

- Express presser foot change: guaranteed time saving

- Compatibility with different types of presser foot: essential to adapt to each project

- Intuitive access to the rotary hook: facilitates troubleshooting

- Micrometric adjustment of thread tension: absolute precision

- Motor heating after 30 minutes of testing: durability alert

Your intuition counts as much as these technical tests!

Budget and long-term profitability

The initial purchase price is just the tip of the iceberg. Maintenance costs and electricity consumption weigh heavily in the balance.

|

Average price guide by leading brands |

|

|

Brand |

Key advantage |

|

Juki |

Absolute industrial reliability |

|

Elna |

Extreme robustness |

|

Janome |

Intuitive ergonomics |

Electronically servo-controlled motors reduce energy costs by 30% compared to mechanical models. Also consider the refurbished second-hand market for spare parts, offering up to 60% savings on consumables.

Leading brands and models on the market: Juki and Janome

Juki DDL machines stand out for their reliability in intensive production, handling up to 5,000 stitches/min without flinching. Their secret? A monoblock frame and synchronized drives for 12-hour days without overheating. Ideal for any industrial sewing machine used continuously. Visit our store to discover a wide range of machines from this Japanese brand.

At Janome, the integrated oil bath works wonders. By immersing the gears in a high-performance lubricant, these models gain 40% more lifespan compared to traditional systems. They are perfect for workshops where the machine runs 24/7.

Boost your productivity with these key accessories:

- Professional needle set with Janome

- Triple feed foot with reinforced claws: non-slip on technical fabrics

- Laser guide for parallel seams: guaranteed millimetric precision

- Juki DDL automatic bobbin winder: time saver for long runs

- Cleaning kit with metal brush: quick hook maintenance

The best creations from these two brands are all available in our Verotex online store.

Optimize daily use: preventive maintenance for longevity

Oil your gears every 10 hours of use and dust off the hooks after each heavy session. Meticulous maintenance doubles the lifespan of your industrial sewing machine – think of it as a mechanical spa session!

A metallic clicking or irregular stitches? It's the rotary hook sounding the alarm. Inspect it every month with a flashlight: deep scratches or rough spots require immediate replacement to avoid total breakdown.

Avoid these common mistakes that prematurely ruin machines:

- Skipping daily oiling: dry friction destroys the gears

- Using domestic needles on leather: guaranteed needle holder breakage

- Manually forcing the handwheel when it jams: guaranteed jamming in the hook

If you use a sewing machine for thick fabrics, be even more rigorous: these models endure greater mechanical stress and require impeccable maintenance. Store your machine away from moisture under a dust cover during extended breaks. The trick that works is to place a silica gel packet in the bobbin compartment to absorb micro-droplets.

You saw it: choosing your industrial sewing machine is first about aligning materials, volumes, and budget. Whether it's a Juki for speed or a Janome for endurance, test the models in-store and consider the overall cost. Tomorrow, your workshop will run at full productivity. All that's left is to take action.

Trust quality online stores like Verotex to have a wide choice of the best brands and models of industrial sewing machines.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.