Table of contents:

Machine tools: this term covers all the accessories, adjustment tools, and maintenance elements essential for the proper functioning of your equipment. Whether you use a sewing machine, an overlocker, or a more industrial device, having the right tools is essential to ensure its durability, precision, and safety.

With a suitable maintenance kit, you can avoid many breakdowns, optimize your settings, and extend the life of your machine. Spare parts, compatible professional tools, and cleaning products like oil or an antistatic brush are among the essentials to have on hand.

In this article, we present a selection of essential tools to maintain, improve, or repair your machine, along with practical advice for choosing the right accessories according to your model. Whether you are a beginner or an experienced user, you will find everything you need here to keep your equipment in perfect condition.

Why use tools adapted to your machine?

Maintaining a machine, whether domestic or semi-professional, is not something to improvise. Using compatible and suitable tools is crucial to ensure optimal operation. Too often neglected, basic tools nevertheless help extend the life of your equipment, avoid breakdowns, and guarantee smooth and precise work.

Preserve the machine's longevity

Using a screwdriver that is too large, a poorly adjusted needle, or an inappropriate lubricant can seriously damage internal components. Conversely, the right tools protect:

- Sensitive parts (hook, bobbin case)

- The drive system (claws, belt)

- The motor (by avoiding mechanical overloads)

A simple machine maintenance kit used properly helps keep your machine functional for 10 to 15 years, or even longer.

Optimize performance and avoid breakdowns

Regular maintenance with the right tools improves:

- The stitch accuracy

- The quiet operation

- The constant sewing speed

- The reduction of jams or tension errors

The right tools also save time and peace of mind, as you can quickly intervene in case of blockage or malfunction.

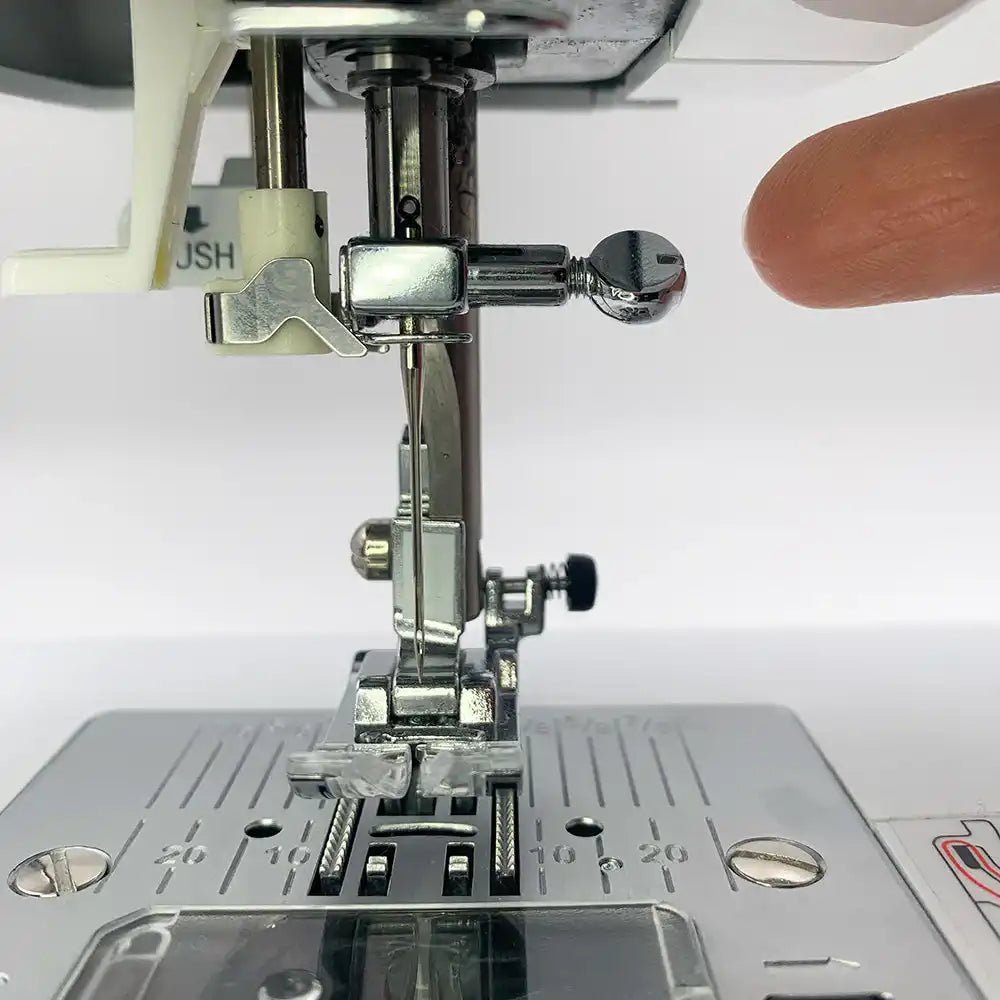

Essential tools for domestic or professional machines

Whether you use a home sewing machine, an overlocker, or an industrial machine, certain tools are essential for routine maintenance, adjustments, or minor repairs. A good basic kit allows you to intervene quickly in case of issues and maintain a good level of performance.

Screwdriver, tweezers, oil, cleaning brush: the tools to get started well

- Screwdriver: to disassemble the case, change the needle, or adjust bobbin tension

- Fine tweezers or tweezers: to remove a stuck thread or position a bobbin

- White mineral oil: to lubricate moving parts (if your machine is not self-lubricating)

- Cleaning brush: to remove lint and dust in the hook or feed dog area

- Soft microfiber cloth: to wipe excess oil or clean the exterior

- Headlamp or LED magnifier: to better see internal details

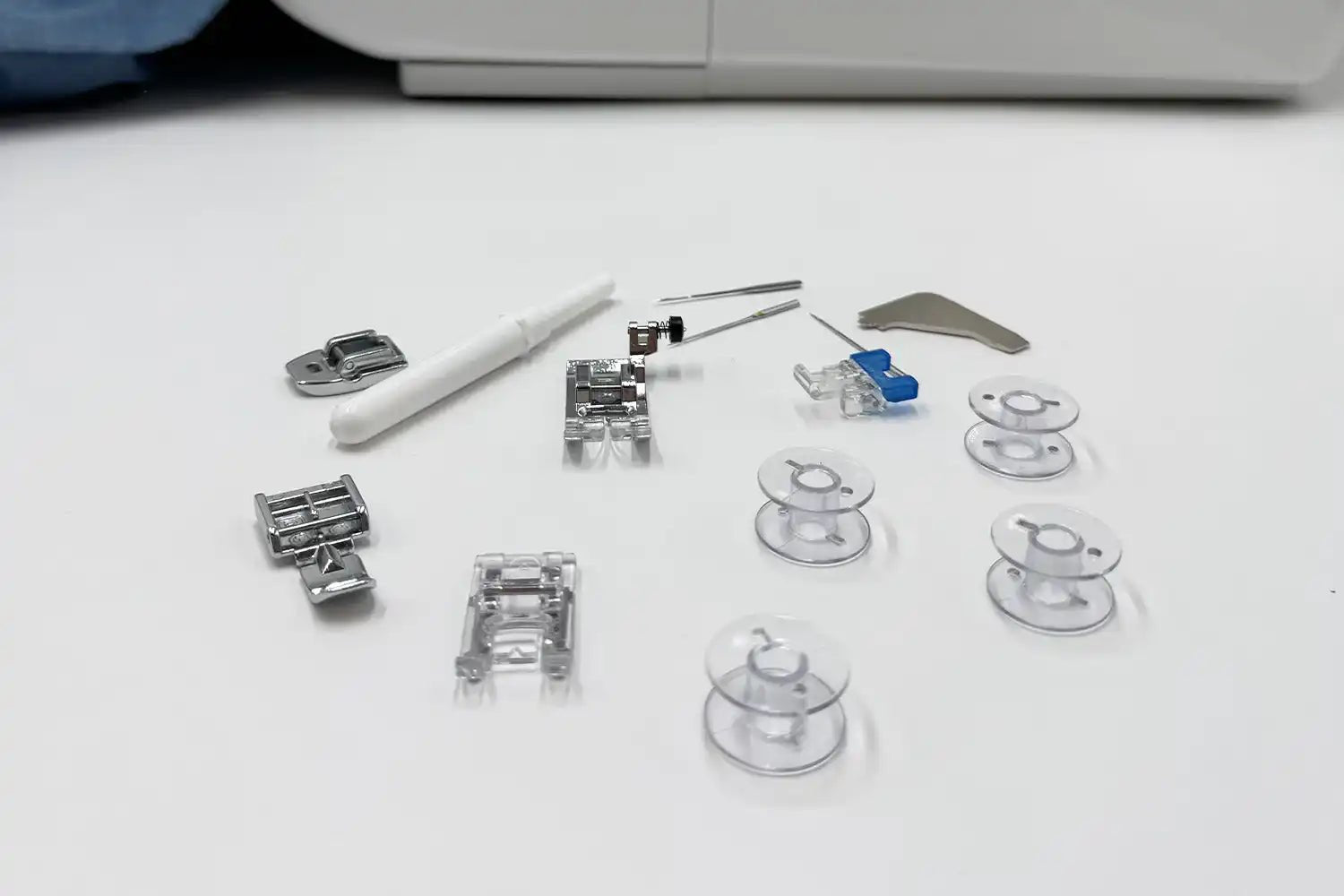

Needles, bobbins, presser feet (for sewing machines)

For sewing machines, some small accessories should be considered as full-fledged tools:

- Set of compatible bobbins with your brand (Juki, Janome, etc.)

- Specific presser feet (zipper, Teflon for leather, bias tape application…)

- Suitable needles: universal, jeans, leather, stretch… and from a reliable brand like Schmetz

- Replacement needle plate: useful if yours is scratched or damaged

Regular maintenance and care: the right actions

Regularly maintaining your machine with the right tools helps prevent premature wear, mechanical noises, and irregular stitches. A simple routine, well applied, ensures smooth and professional sewing, whatever the model used.

When and how to oil?

If your machine is not industrial, it must be oiled manually. Here are the recommendations:

- Use only odorless white mineral oil

- Apply a drop on moving parts (needle shaft, hook, bobbin case)

- Always wipe off excess to avoid stains on fabric

Recommended frequency:

- Every 3 months for moderate use

- Every month for intensive use

For industrial oil-bath machines, it is necessary to check and replace the oil every 2 years.

Clean sensitive areas (feed dogs, case, motor)

Areas to clean regularly:

- Under the feed dogs (thread and fabric dust)

- Around the bobbin case

- Under the needle plate

- Ventilation grid or motor (with a dry brush)

Recommended maintenance frequency according to usage

| Machine use | Oiling | Deep cleaning |

|---|---|---|

| Occasional (1x/week) | Every 6 months | Every 3 months |

| Regular (1h/day) | Every 3 months | Every month |

| Intensive (pro/workshop) | Every month | Every week |

FAQ about machine tools

What tools come with a new machine?

Generally, a machine comes with a small basic kit: screwdriver, seam ripper, bobbins, and sometimes a standard foot or a brush.

How often should I maintain my machine?

It depends on your usage. Every 3 months for moderate use, every month if you sew intensively. Cleaning is recommended after each project.

Can I use standard tools?

Not always. Prefer tools compatible with your machine's brand (e.g., Juki, Janome) to avoid any damage or poor fitting.

Where to find compatible accessories?

At an authorized dealer like Verotex, you will find tools and accessories suited to the machines you use.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.