Table of contents:

Are the threads on your sewing machine stubbornly forming unsightly loops? This malfunction is not random and usually appears as an excess of loose thread on the front or back of the fabric. It often indicates an imbalance in thread tension or incorrect threading.

Here, we will break down the causes of the thread looping problem on your sewing machine and offer you quick and effective solutions to fix it. We provide the best advice to correct this issue, ensuring regular and strong stitches.

How to identify the different types of loops?

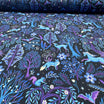

When facing a sewing machine thread looping problem, careful observation of the stitching can provide valuable clues. Depending on the location of the loops, on top or underneath the floral fabric, and their appearance, it is possible to trace back to the cause of the malfunction. This table guides you to recognize each type of loop, understand its origin (tension, threading, bobbin, needle…) and apply the necessary adjustments or actions to effectively fix it.

|

Table of different types of thread loops, their possible locations on the work, |

||

|

Type of loop / Location |

Probable cause |

Diagnostic / Adjustment solution |

|

Loops on the underside of the fabric |

Upper thread tension too loose |

Check the upper thread threading, |

|

Loops on the top of the fabric |

Bobbin thread tension too loose or |

Check that the bobbin is correctly |

|

Irregular loops or skipped stitches |

Dull needle, incorrect threading, |

Replace the needle with a new one |

|

Thread knots |

Incorrect threading, poor quality thread, |

Re-thread the machine completely, |

|

Thread tangling under the fabric |

Incorrect bobbin tension, |

Clean the bobbin case to |

The main causes of thread looping in your sewing

When you encounter a sewing machine thread looping problem, it is often difficult to immediately identify the cause. However, this common issue can quickly compromise the quality of your seams. Before panicking, know that several factors can be behind this annoyance. Let's explore together the main causes to check to restore neat and even stitching.

Thread tension problems: the main culprit

Poor thread tension unbalances the forces between the upper thread and the bobbin thread, which can cause unsightly loops on your projects.

If the tension is too tight, it may pucker the fabric and break the thread. On the other hand, if it is too loose, it leaves loose stitches. Proper adjustment of the thread on your sewing machine is therefore essential to ensure neat and durable seams. Check the setting regularly, especially when changing fabric.

Is your sewing machine giving you trouble with the thread? Contact Verotex professionals today for a quick and effective solution.

Incorrect threading: common mistakes to avoid

When threading, watch out for the following mistakes:

-

Forgetting an important thread guide

-

The crowbar remains lowered during threading

-

The upper thread is not properly engaged in the tensioner

-

The bobbin thread is not held during the first stitch

Threading easily disrupts the sewing machine tension. To avoid this problem, follow the device’s diagram that guides the thread from the spool to the needle without skipping steps.

Bobbin-related problems: installation and winding

An unevenly wound bobbin creates unbalanced tensions. The upper and lower threads must interlock harmoniously to avoid loops.

A poorly positioned bobbin case or a bobbin thread not properly engaged causes irregular stitches. If your sewing shows sudden irregularities, there is likely a bobbin problem with your sewing machine. Always check the thread direction and the cleanliness of the bobbin case.

Needle choice and its impact on stitch quality

A defective or poorly suited needle causes skipped stitches. If the needle tip is blunt, it may pull the thread instead of piercing it cleanly.

Choose your needle according to the fabric: flat needle for cotton, sharp for tight fabrics, ballpoint for knits. Also, make sure to use good quality sewing threads suited to your project to avoid breakage or unwanted loops. A good needle and thread combination prevents loops.

Practical solutions to fix the thread looping problem

A sewing machine thread looping problem can quickly turn your sewing session into a headache. Fortunately, a few simple steps often solve it. By correctly adjusting the thread tension and checking the threading, you can achieve neat and even stitches. Discover here practical solutions to effectively fix this common malfunction.

How to properly adjust the thread tension?

To test the thread tension, sew a fabric sample. The upper thread and the bobbin thread should interlock in the middle of the fabric, and a balanced stitch prevents loops.

Adjust the tension with the adjustment dial. If it is too tight, it puckers the fabric, and if it is too loose, it leaves loose stitches. Test after each adjustment to find the right balance.

For any breakdown or question regarding your sewing machine, the experts at Verotex are here to help. Feel free to contact us!

Check and correct your machine's threading

Lift the presser foot, then position the spool and follow the threading diagram. Next, pass the thread through the guides before descending towards the needle and pull 10 cm of free thread.

|

Specific problem |

Targeted solution |

|

The thread escapes from the thread guide |

Check the thread guide locking or replace it if damaged |

|

The thread does not pass through the tensioner |

Clean the tensioner and reinsert the thread according to the user manual |

|

Sensor problem after threading |

Restart the machine or reset the threading settings |

Correctly install the bobbin and adjust its tension

To properly install your bobbin, open the compartment and insert the bobbin ensuring the thread direction (usually counterclockwise). Then, pull the thread into the slot and close the case.

-

The thread breaks suddenly during sewing

-

Irregular or skipped stitches

-

Presence of loops under the fabric

Maintenance and prevention tips for perfect stitches

To avoid any sewing machine thread looping issues, maintaining your equipment plays a crucial role. Regular maintenance and choosing thread suited to your fabric not only prevent malfunctions but also ensure smooth and precise sewing. Here are some practical tips to keep your machine in perfect condition and guarantee flawless results for every project.

Regular maintenance of your sewing machine

Remove lint trapped under the bobbin case or around the feed dogs and remember to clean after each project or every two to three uses depending on intensity. With a clean machine, you avoid thread tension and incorrect threading problems.

Also check the manual to identify oiling points. For optimal machine operation, use special sewing machine oil and apply a few drops on the rails and pivots. Regular lubrication protects mechanisms and prevents skipped stitches.

The presser foot is an important accessory to improve stitch quality and avoid loops.

Don’t let a malfunction ruin your work. Verotex’s qualified technicians are ready to assist. Call us now!

Choosing the right thread for your sewing project

Cotton thread suits natural fabrics like linen or cotton, while polyester is suitable for synthetic materials. Choosing a French cotton thread limits irregular tension problems and prevents loop formation.

Another way to avoid the problem of thread looping on a sewing machine is a good combination of thread, fabric, and needle: a flat needle is suitable for cotton, a sharp point works for tight fabrics, and a ballpoint needle is for stretch fabrics. A good combo prevents unsightly loops and ensures neat stitches.

The problem of thread looping on the sewing machine has three main causes: incorrect tension, improper threading, or incorrectly installed bobbin. Try these simple solutions to get clean stitches again.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.