Table of contents:

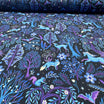

The tear-proof slit is a finish used to reinforce a discreet opening on a garment. It is mainly found at the bottom of a sleeve cuff. It is made with a bias tape that prevents fraying and ensures a clean and durable finish. This detailed guide explains how to proceed step by step.

How to prepare the slit?

- Mark the location of the slit

Mark the future slit on the fabric by drawing a vertical line and cutting along it.

Set the height of the slit according to the garment pattern.

- Iron the bias tape

You will iron your strip to create a bias tape, then iron it again folded in two.

How to sew the bias tape on the slit?

- Position the bias tape correctly

Sandwich the sides of your slit inside the bias tape. When you reach the tip of the slit, position the bias tape 1 or 2mm from the edge to avoid creating small folds.

- Sew the bias tape

In one go, sew the bias tape 1mm from its edge.

How to form and finish the tear-resistant slit?

- Old tip of the slit

Fold the bias wrong side against wrong side, aligning the edges well.

Flatten with the iron to mark the fold well and sew the small corner diagonally to secure the slit.

- Finish the slit

Carefully iron the slit to properly shape the bias.

Check that the slit is even and that the bias neatly covers the edges.

The tear-resistant slit is an essential technique to reinforce an opening on a garment while providing a neat and durable finish. Thanks to the addition of a bias strip and precise stitching, you get a strong slit that resists wear and fabric tension. This method is ideal for shirt cuffs requiring a neat opening.

The cuff of a shirt is often made in one or two parts in the form of a rectangle. This guide presents the essential steps to create a neat and durable shirt cuff, with finishes adapted according to the style of the garment.

How to prepare the pieces for the shirt cuff?

- Prepare the bottom of the sleeve

The bottom of the sleeve must have a tear-resistant slitmaple and two flat pleats.

- Reinforce the cuff

Fuse the wrong side of the cuff.

Form a filled corresponding to the seam allowance, wrong sides together.

How to assemble and attach the wristband?

- Attach the wristband

Fold the wristband right sides together and join the small widths with a straight stitch 2.5 length and a backstitch.

Start sewing at 1 cm from the edge , corresponding to the seam allowance.

Cut the threads, turn the wristband right side out, shape the right angles, and press carefully.

- Position the wristband on the sleeve

Pin the unfolded edge of the wristband right sides together with the sleeve hem.

Position the wristband ends against the slit and adjust the sleeve pleats.

The front part of the slit folds back on itself for a clean old-style overlap.

- Attach the wristband to the sleeve

Sew the wrist end to the sleeve hem.

Check that the pleats, slit edges, and seam are properly aligned.

Use a straight stitch 2.5 length and make a backstitch.

Cut the threads and press.

How to finish the cuff details?

- Attach the preformed edge of the cuff

Turn the sleeve inside out and press it seam allowance towards the cuff.

Shape the cuff well, then its preformed edge to cover the assembly seam.

- Make a topstitch

For a more aesthetic result and to completely close your cuff, make a topstitching 2 mm from the edge.

Use a elongated straight stitch.

How to add buttons and finish the cuff?

- Attach the buttonholes and buttons

Mark the position of your button and buttonhole using chalk or a erasable pen.

Embroider the buttonhole(s), then attach the buttons.

Press the cuff to ensure a flawless finish.

Repeat the steps for the other sleeve.

Conclusion

Making a shirt cuff requires precision and care. With this guide, you will learn how to sew a sturdy and elegant cuff with professional finishes. Whether you choose topstitching or discreet seams, these steps ensure a neat and durable result.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.