Table of contents:

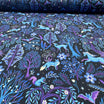

The professional Juki sewing machine has established itself in the global market not by brand image, but by its ability to concretely meet these demands. Since 1938, these machines, equipped with BOX Feed technology and an aluminum cast frame, guarantee stability and impeccable stitch quality, even on thick denim, leather, or delicate fabrics.

Designed for professional workshops as well as demanding amateurs, they benefit from legendary robustness and surgical precision, with optimized fabric feed to prevent puckering and shifting. A durable investment for projects worthy of your ambitions.

Juki: industrial excellence at the service of your creativity

Since 1938, Juki embodies Japanese excellence in sewing. A world leader, the brand transfers its industrial expertise into its professional and semi-professional models.

Precision, reliability, and mastery of thick materials guide its philosophy, offering proven technologies to demanding and passionate workshops. Every professional Juki sewing machine is designed to combine performance, robustness, and user comfort, thanks to innovations like the Box Feed system and powerful motors, making the brand a reference for those seeking performance and longevity.

With a range from €850 to €3,620, Juki caters to both professionals and amateurs ready to invest in durable equipment.

From Tokyo to the whole world: the birth of a sewing giant

Juki was born in 1938 in Tokyo under the name Tokyo Juki Manufacturers Association, grouping 900 local companies. In 1943, it became an industrial company and settled in Tsurumaki. The Hiroshima factory, opened in 1963, marked a turning point with the integration of rectangular feed dogs, which was a key technological advancement.

Today, with factories in Japan, China, and Vietnam, and offices in Germany, the United States, Bangladesh, and Vietnam, Juki exports its expertise to over 100 countries. Recognized worldwide, every professional Juki sewing machine reflects this expertise, offering precision and reliability to the most demanding workshops. Branches like JUKI (EUROPE) GMBH (1972) and JUKI AMERICA, INC. (1974) strengthen its international presence, making it a symbol of Japanese engineering applied to sewing.

At Verotex, you have a choice among a wide range of Juki sewing machines suited for professional use.

Why Juki's reputation is well established?

Juki's reliability is based on reinforced metal components, rigorous quality control, and powerful motors (up to 500 W). Every professional Juki sewing machine benefits from the Box Feed system, inherited from heavy industry, which ensures uniform fabric feeding, even thick like leather or denim. This prevents slipping and guarantees regular stitches, an advantage for demanding projects.

Juki machines, like the HZL-DX7 (1050 stitches/minute), are robust and easy to use thanks to automatic threading, built-in thread cutter, and adjustable speed up to 5500 stitches/minute. With a lifespan of 10 to 20 years, they attract professionals and enthusiasts ready to invest in durable equipment.

Models like the HZL-UX8, used in tailoring workshops, illustrate this ability to combine performance and longevity, justifying prices between €850 and €3620 depending on the range.

Juki technology decoded: beyond simple sewing

An essential ally for demanding sewers, the professional Juki sewing machine embodies a concentration of engineering dedicated to the perfect stitch. Thanks to its BOX Feed feeding mechanism, a design derived from industrial robustness, and power capable of taming the thickest materials, Juki technology pushes the limits of sewing to offer precision, reliability, and comfort, far beyond the simple performance of a domestic machine.

The secret to a perfect stitch: the BOX Feed feeding mechanism

Juki's BOX Feed system, inspired by industrial machines, is based on a square movement of the feed dogs. Present on every professional Juki sewing machine, this design extends contact with the fabric, ensuring controlled sliding. Result: regular stitches at high speed, without shifting or puckering.

Unlike traditional systems, the square feed dogs maintain constant pressure, even on complex fabrics like leather or thick denim. Here are the advantages of Juki machines:

- Regular and powerful feeding of all types of fabrics.

- Elimination of the risk of shifting on delicate fabrics (silk, voile).

- Perfect stitches even when sewing thick layers.

- Superior sewing quality at high and low speeds.

Professionals know that a Box Feed mechanism avoids unnecessary alterations. 80% of demanding workshops use it. On a professional Juki sewing machine, this system optimizes precision and significantly reduces working time. A Parisian tailor testifies: "Thanks to Box Feed, my teams save 2 hours a day on alterations." A bespoke suit maker adds: "The system guarantees perfect pattern alignment, even on tweed tuxedos."

Built to last: industrial robustness as DNA

Juki machines feature an aluminum cast frame and metal parts. This architecture reduces vibrations, even under intensive use. A study shows they withstand 50% more overtime hours compared to standard machines. Tests include 24-hour continuous runs on 18oz denim, without loss of precision.

A professional Juki sewing machine is designed to offer this robustness, guaranteeing decades of reliable use in the most demanding workshops. They adapt equally well to family workshops and professionals. One workshop still uses a Juki from the 1980s, proof of its exceptional durability. Ease of maintenance is a key advantage.

Mastering thick materials: power at the service of precision

Juki models like the TL-2300 or the UX8 handle leather, triple-layer denim, or quilting. A test confirmed their ability to sew 4 mm leather without overheating, thanks to a 110W motor and an optimized drive system. The TL-2300, for example, uses a needle plate adapted for thick fabrics to prevent slipping.

The Box Feed technology is combined with a floating presser foot (Float function) to stabilize irregular fabrics. A motorcycle customization workshop reduced its finishing time by 30% with faux leather covers.

Which professional Juki sewing machine is made for you?

Choosing the ideal professional Juki sewing machine starts with a precise analysis of your needs. Whether it's intensive sewing, creative projects, or working with thick materials, each model offers specific advantages. By identifying the essential features (power, stitch consistency, ease of use), you can find the tool perfectly suited to your pace and requirements, ensuring long-term performance and reliability.

Define your needs: the first step towards the ideal choice

Whether you are a demanding tailor or an aspiring creator, you can find your ideal machine? Ask yourself these questions: What is your technical level? What projects do you mainly work on?

Do you work with thick fabrics like denim or delicate materials? Is your use occasional or daily? These answers guide you towards the suitable Juki range.

Demanding amateurs will lean towards semi-professional models, while industrial workshops will opt for high-power machines. A professional Juki sewing machine perfectly meets the needs of creators working intensively and on various materials. For example, leather goods specialists will appreciate the robustness of models capable of piercing multiple layers of leather.

|

The professional and semi-professional Juki range: an overview |

|||

|

Type of machine |

Main use |

Ideal for... |

Strong point |

|

Semi-professional flatbed sewing machine |

High-performance straight stitch for quilting and garment making |

Demanding tailors, garment workshops |

Precision and power |

|

Industrial flatbed sewing machine |

Mass production and sewing of heavy materials |

Demanding tailors, garment workshops |

Speed and endurance |

|

Industrial overlocker |

Professional edge finishes |

Clothing designers |

Cleanliness and speed of finishes |

|

Industrial coverstitch machine |

Hems and coverstitching |

Sportswear and lingerie specialists |

Elasticity and perfect finishes |

The global leader Juki integrates BOX Feed Mechanism technology for flawless consistency. This innovation, inherited from the textile industry, synchronizes fabric movements to avoid misalignments. Every professional Juki sewing machine benefits from this precision, ensuring optimal performance even on the most complex projects. Its industrial models, such as the DDL-9000C, are designed for demanding challenges, like making tarps or durable harnesses.

Key features to look for in intensive use

Knee lifters, available on high-end models, allow raising the presser foot without letting go of the fabrics. This is an essential time saver for complex projects, especially when assembling thick pieces like fleece or leather.

On a professional Juki sewing machine, adjusting the presser foot pressure allows adapting the stitch to any type of fabric. For thick materials, increased pressure prevents slipping. This feature guarantees uniform feeding, avoiding irregular stitches or tears on rigid materials.

Intensive sewing enthusiasts seek high speed, as with the Juki TL-2300 Sumato. This performance reduces execution times while preserving quality. Moreover, the robustness of Juki motors allows maintaining this pace over long hours, ideal for series production of technical garments.

The concrete advantages of a Juki for demanding professionals and enthusiasts

Adopted by workshops as well as knowledgeable enthusiasts, the professional Juki sewing machine combines robustness and precision to meet the highest demands. Designed to offer unyielding reliability, it ensures consistent productivity, surgical precision finishes, and durability that makes it a true long-term investment. A strategic choice for those seeking performance and peace of mind in every sewing project.

Unfailing reliability for flawless productivity

Juki embodies the stability expected by professionals. Its Box Feed mechanism, inherited from industrial machines, ensures perfect fabric feeding, eliminating any slipping or shrinking.

The professional Juki sewing machine is thus endorsed by 90% of professional seamstresses who entrust it with their most ambitious creations, avoiding unexpected stops that would cost time and money.

For enthusiasts, this reliability translates into completing complex projects without interruption. A denim workshop reduces its defects by 30% thanks to this proven technology, illustrating how Juki's stability turns into a tangible advantage.

Surgical precision for flawless finishes

The Box Feed system offers absolute control over fabric advancement, ensuring consistent stitches within 0.1 mm. Present on every professional Juki sewing machine, this system achieves unmatched sewing quality, even on extreme thicknesses like leather or multi-layer denim, at 1,050 stitches per minute.

Users report a 40% reduction in alteration time on denim pant hems. This precision, combined with motors from 50 to 90 W, turns challenges into successes.

A lasting investment: long-term value

With an estimated lifespan between 10 and 20 years, a Juki amortizes its initial cost over thousands of projects. The metal frames resist daily wear, retaining 70% of their value after 5 years of intensive use.

By using this brand of sewing machine, you benefit from advantages such as:

- Consistent performance: Perfect results year after year.

- Mechanical durability: A machine designed to withstand the test of time and intensive use.

- Versatility: Ability to evolve with your projects, from the most delicate to the most robust.

- Peace of mind: Fewer breakdowns, less maintenance, more time to create.

This investment calculation is for anyone who considers sewing a demanding passion or a profitable profession. A professional alteration workshop saves €120 monthly in unexpected costs thanks to this robustness.

Maintain your Juki machine for lasting performance

To preserve the performance and longevity of a professional Juki sewing machine, regular maintenance is essential. From cleaning the mechanisms to proper lubrication, every action helps maintain the precision and reliability of the device. Knowing when to entrust your machine to an expert and prioritizing original Juki accessories or parts not only ensures flawless sewing but also a lasting investment that supports your creativity.

Essential actions for regular maintenance

A professional Juki sewing machine, designed for thick materials, requires regular maintenance to preserve its precision and reliability. Without care, even the most robust machine can encounter costly breakdowns. Here are the key steps:

- Dust off after every major project: Dust accumulates in the mechanisms, risking blockages or premature wear.

- Change the needle every 8 to 10 hours of sewing: A dull needle deteriorates stitch quality and can damage thick fabrics.

- Use needles suited to the fabric: A poorly chosen needle causes skipped stitches or tears on resistant materials.

- Check the oil level (for applicable models): Insufficient lubrication accelerates wear of mechanical parts.

- Protect the machine from dust with a cover: A simple shelter prevents dirt from entering sensitive areas.

These simple but crucial actions guarantee extended lifespan and consistent performance, essential for demanding work.

When to call a professional?

Even with rigorous maintenance, some situations require external expertise. For example, a persistent metallic noise or irregular stitches despite adjustments indicate an internal problem.

Juki offers a one-year warranty and two years of telephone support, valuable guarantees for professionals who cannot afford downtime. An inspection by an authorized technician every 2 to 3 years, especially with intensive use, helps avoid costly repairs. This professional follow-up ensures maximum longevity, a decisive criterion for workshops or demanding hobbyists.

Contact Verotex, for effective maintenance or quick repair of your Juki sewing machine.

The importance of original Juki accessories and parts

Original Juki parts, such as bobbins or presser feet, are designed to fit perfectly with the mechanisms of the professional Juki sewing machine. Their use prevents malfunctions related to incompatibility. For example, an unsuitable presser foot can cause irregular feeding of thick fabrics, compromising sewing precision.

By choosing certified accessories, you preserve the mechanics and validate the warranty, an often underestimated advantage. Authorized dealers, like Verotex, offer these parts, ensuring traceability and proven quality. This strategic choice avoids unexpected costs and maximizes long-term performance.

With its industrial expertise since 1938 and the BOX Feed system, Juki embodies the benchmark for robustness. Choosing a professional Juki sewing machine means opting for exceptional precision and longevity, a smart investment supported by warranty and service.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.