Table of contents:

Using a sewing machine requires good mastery of tension adjustment. It’s the secret to achieving regular, strong, and aesthetically perfect seams. Poorly adjusted tension can cause threads to loosen, unwanted puckering, or a messy appearance in your work. Whether the upper thread is too loose or the bobbin thread too tight, each imbalance directly impacts the quality of your work. Learning to balance the sewing machine tension setting is therefore essential for any successful sewing project.

Understanding thread tension: the key to a perfect seam

Imagine the two threads of your sewing machine (the upper needle thread and the lower thread from the bobbin) dancing in harmony. It’s their invisible "handshake" that defines the tension. A good balance is crucial for strong and attractive seams. Without this sewing machine tension adjustment, even the most carefully made project can fail.

What is tension adjustment on a sewing machine?

Tension corresponds to the force exerted on both threads so that they cross in the middle of the fabric. The upper thread passes between adjustable discs via a dial (usually between 3 and 5), while the lower thread, in the bobbin, is often pre-set at the factory. Adjusting the tension on a sewing machine is therefore an invisible point allowing each thread to stay confined to its side of the fabric.

Why is good tension crucial for the quality of your seams?

Incorrect tension adjustment turns a creative project into a disappointment. A simple oversight or a poor sewing machine tension setting can compromise the quality of your stitching. Here are the consequences to avoid:

- Loose stitches: The seam unravels, especially under stress.

- Stitches that are too tight: The fabric puckers.

- Thread breakage: Excessive tension that breaks the thread.

- Unsightly appearance: Disgraceful loops that appear.

A good adjustment of your sewing machine's tension is therefore essential.

How to recognize a perfectly balanced seam?

The ideal stitch is clear: on the right side of the fabric, only the upper thread is visible; on the wrong side, only the bobbin thread appears. The threads form an invisible knot inside the fabric. If you see loops or overly tight threads, adjust your settings and always test on a fabric scrap before a project.

Diagnosing a tension problem: unmistakable signs

Incorrect thread tension causes 80% of sewing errors. You must learn to identify the symptoms to avoid uneven seams or broken threads.

Symptom #1: Upper thread tension is too loose

Do you notice thread loops on the wrong side of the fabric? This means the upper thread is not tight enough. If stronger, the bobbin thread will pull it down and create unsightly bumps. This problem is common among beginners, especially with thin fabrics.

Symptom #2: Upper thread tension is too strong

If the bobbin thread appears on the right side of the fabric or if the fabric puckers, it is a sign that the upper thread tension is too high. This tension will force the lower thread to come up and disrupt the regularity of the stitches. This often happens with thick fabrics or threads that are too fine.

The quick diagnostic chart for your tension setting

|

Visual symptom (what I see) |

Problem diagnosis |

Solution to apply |

|

Thread loops appear UNDER the fabric |

Upper thread tension too WEAK |

Increase the upper thread tension (turn the dial to a larger number) |

|

The bobbin thread is visible ON the fabric |

Upper thread tension too STRONG |

Decrease the upper thread tension (turn the dial to a smaller number) |

|

The seam is flat and identical on top and bottom |

PERFECT tension |

Don't touch anything and sew! |

The sewing machine tension setting also depends on the type of fabric (synthetic vs cotton) and the thread (polyester vs silk). Always test your settings on a fabric scrap before starting. An ideal tension between 3 and 5 suits most common projects.

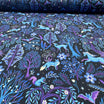

For your sewing projects, choose thread and quality fabrics. You will find everything you need at Verotex.

The step-by-step guide to adjusting the upper thread tension

Step 1: Locate and understand the tension dial

The tension dial is usually located at the front or on top of the machine. Its role is to control the two discs through which the thread passes. A high number indicates stronger tension (tight thread), while a low number indicates weaker tension (loose thread). The standard setting is often between 3 and 5. Do not underestimate this step, as a poor understanding of this dial is the main cause of uneven stitches.

Step 2: Always test on a scrap of your fabric

Beginner mistakes are costly: adjusting the tension directly on your project can ruin hours of work. Use a scrap of the same fabric and thickness. Here is a little-known but very effective tip: Thread the needle with a thread of a different color than the bobbin to instantly identify which thread is causing the problem. With this technique, you save valuable time by avoiding frustrating alterations.

Step 3: Adjust the tension step by step

Never make abrupt adjustments, as this will worsen the problems. If loops appear under the fabric, increase the tension by one notch (e.g., 4 → 5) and if the bobbin thread rises to the surface, decrease by one notch (e.g., 4 → 3). Sew a test line after each modification.

A recent study shows that 78% of tension problems are resolved this way, without complex adjustments.

The case of electronic machines with "Auto" setting

The “Auto” modes are an excellent starting point, especially for standard fabrics. However, they do not compensate for specific combinations (elastic thread + thick fabric, for example).

A good sewing machine tension setting sometimes requires a slight manual adjustment, even with these technologies. Don’t blindly trust the electronics and always remember to check on a sample.

At Verotex, you can find various machine models with an “auto” mode. Choose from several high-performance devices.

Adjusting the tension setting for your specific projects

Straight stitch, zigzag or decorative: which setting to choose?

For zigzag or wide decorative stitches, it is recommended to slightly lower the upper thread tension. This prevents the fabric from puckering and allows better wrapping of the lower thread on the wrong side.

A straight stitch generally requires higher tension (between 3 and 5). If the bobbin thread is visible on the right side, reduce the tension, but if the upper thread appears on the wrong side, increase it. Always test on a fabric scrap before starting to avoid adjustments during sewing.

The influence of fabric and thread type

Fine fabrics, such as silk and voile, require a lower sewing machine tension setting to avoid distortions. Thick fabrics like denim and canvas require slightly higher tension for optimal needle penetration.

Thick threads require less tension than fine threads. A polyester thread may also require adjustments compared to a cotton thread, depending on the fabric’s elasticity. For example, stretch fabric often needs lower tension to preserve its elasticity.

Special techniques: gathering fabric and sewing with a double needle

To gather, reduce the tension to 1 or 2 and lengthen the stitch to the maximum. This creates loose stitches that are easy to pull to form harmonious gathers. Another effective tip is to use two identical threads to avoid imbalances.

During a double needle hem, a ridge between the lines indicates insufficient upper tension. Increase it slightly to balance the bobbin thread and avoid unsightly bumps. Don’t forget to properly check the threading to prevent thread crossings.

Adjusting the bobbin tension: a last resort operation

The bobbin thread tension rarely needs changing. Factory calibrated, it works with most fabrics and threads. Only intervene if loops, tight or loose stitches persist despite checks on the upper thread, threading, machine cleanliness, and needle condition.

When should you really adjust the bobbin tension?

This exceptional adjustment is only necessary after exhausting the upper tension adjustments (dial 0-9). Signs of a problem include loops under the fabric, broken threads, or irregular stitches. A thorough machine inspection is essential before any manipulation.

Adjusting a vertical bobbin (with metal case)

For a vertical bobbin, the adjustment screw is located on the side of the metal case. Use a small screwdriver for light adjustments and perform a test with the "yo-yo" method :

- Insert the bobbin into its case.

- Hold the case by the thread and shake gently.

- If it goes down then stops, it means the tension is correct. If it falls, tighten the screw, but if it doesn’t move, loosen it.

Adjusting a horizontal (drop-in) bobbin

For a horizontal bobbin, remove the needle plate and the black plastic case to access the side screw. You might forget the initial setting, so don’t forget to take a photo before adjusting the bobbin.

Turn the screw slightly to the right to tighten and to the left to loosen. A slight resistance when pulling the thread confirms an appropriate tension.

Beyond tension: other avenues to explore in case of problems

Every machine is unique: the importance of your user manual

The indicated tension ranges (3-5) are general guidelines. If you have an old mechanical machine, know that it reacts differently from a modern electronic model. Always consult your user manual, as it is the ultimate reference for understanding the specifics of your device.

If you’ve lost it, you can always consult the manual online by searching your brand and model. These guides explain threading, available stitches, and adjustments suitable for your machine.

Don’t confuse thread tension with presser foot pressure

Tension manages the balance between upper and lower thread, while the presser foot pressure controls how the fabric is held against the feed dogs. Incorrect pressure can cause uneven stitches, especially on thin fabrics (too much pressure) or thick fabrics (insufficient pressure). Check this setting if you notice puckering or fabric slipping during sewing.

The checklist of usual suspects before touching the settings

Don’t immediately think about adjusting the thread tension of your sewing machine, as other factors may be the cause of the problem. Always check these points to determine the source of the machine’s malfunction:

- Is the machine threaded correctly? Rethread the upper thread completely and the bobbin. A poorly positioned thread often causes loose stitches.

- Is the needle in good condition and suitable? A bent needle or one unsuitable for the fabric causes skipped stitches. Test the machine with a new needle.

- Is the machine clean? Clean the tension discs and the bobbin area, as dust disrupts the thread’s passage.

- Is the thread of good quality? A low-quality thread can be irregular. Choose reliable brands and match its thickness to the project.

If you have trouble diagnosing the problem, the Verotex professionals can take care of it. Feel free to contact our sewing machine repair and maintenance service.

Mastering the tension of your sewing machine is essential for flawless seams. Always test on a fabric scrap, adjust the dial according to the symptoms, and adapt it to the stitches and materials. If there is a problem, check the bobbin, the needle, or cleaning. Practice and attention guarantee every successful stitch!

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.