Table of contents:

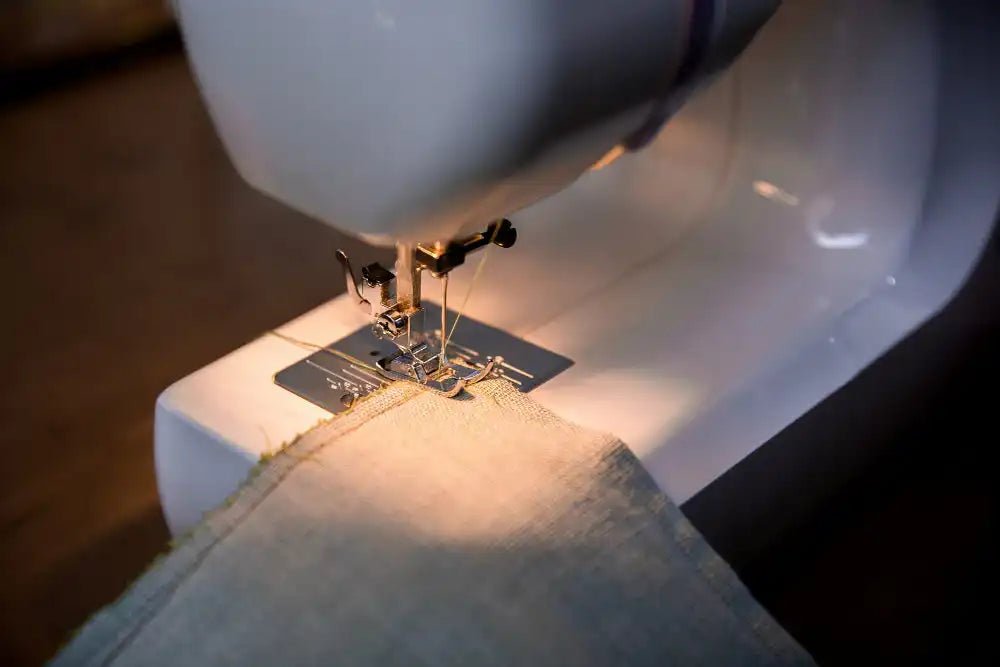

Is your sewing machine no longer making stitches correctly? Don’t let this setback ruin your project! We will thoroughly examine the most common culprits of this scenario.

Discover the frequent causes related to thread tension, the needle, or threading and adopt a pragmatic approach to diagnose and solve these problems. This article offers concrete steps to optimize your machine's performance and prevent recurring breakdowns.

Common problems when your sewing machine skips stitches

Proper sewing machine maintenance is essential to prevent your machine from no longer making stitches correctly. When your sewing machine stops making stitches properly, several common causes can explain this malfunction. The needle may be dull, bent, or not suitable for the fabric.

Another cause can be the thread tension. If it is too loose or too tight, it can affect stitch quality. Incorrect threading or a bobbin problem also disrupts sewing. These simple-to-check elements often allow you to solve the problem quickly.

A methodical diagnosis is important to identify the source of the problem. Ignoring signs of poor adjustment can lead to uneven seams, puckering, or even damage to the fabric.

Incorrect tension causes loose or tight stitches, compromising the strength of the seam. It is important to act quickly on these settings to ensure optimal results. Regularly checking key components prevents repeated breakdowns and extends the machine's lifespan.

Do you want to have complete control over the operation of your sewing machine? Sign up for Verotex courses.

|

Main causes and symptoms of stitch problems on a sewing machine |

||

|

Cause |

Symptom |

Solution |

|

Upper thread tension too loose |

Thread loops under the fabric |

Increase the upper thread tension |

|

Dull or bent needle |

Skipped or irregular stitches |

Replace the needle every 8-10 hours of sewing |

|

Wrong type of needle for the fabric |

Poor quality stitches |

Match the needle to the fabric |

|

Bobbin thread tension too loose |

Thread loops on top of the fabric |

Adjust the bobbin tension or |

|

Incorrect thread threading |

Thread jam or missing stitches |

Redo the threading following the |

|

Poor quality thread |

Frequent thread breakage |

Use high-quality threads |

|

Dust accumulation |

Fabric slipping or jamming |

Clean the bobbin compartment, |

|

Lack of maintenance |

Recurring stitch problems |

Schedule maintenance every 2-3 months |

Diagnosis and resolution of irregular stitch problems

When your sewing machine no longer makes stitches correctly, it is essential to quickly identify the source of the problem. Irregular stitches often come from defects related to the needle or threading, as well as incorrect tension settings of the thread or bobbin. Here is how to diagnose these common causes and resolve them effectively to restore flawless sewing work.

Problems related to the needle and threading

As mentioned earlier, a damaged needle or incorrect threading of the upper thread disrupts stitch formation. A bent or dull needle causes skipped stitches, while a thread improperly inserted in the tension guides causes jams.

Also make sure to choose your needle according to the fabric: knowing which needle for which fabric helps prevent many malfunctions. Check these elements before undertaking more complex adjustments on your sewing machine.

Carry out these checks or adopt these good habits before using your machine:

- Check the needle condition: replace it if it is bent, dull, or improperly inserted to avoid skipped stitches.

- Use the correct needle for the fabric: choose a needle suited to the thickness and type of fabric for optimal sewing.

- Strictly follow the upper thread threading path: make sure the thread passes through all guides and tension discs.

- Check the bobbin winding: evenly wound thread ensures smooth unwinding and prevents knots under the fabric.

- Properly insert the bobbin into its case: follow the direction of unwinding and the notches provided to avoid stitch problems.

To replace the needle, loosen the screw, remove the old one, and insert a model suitable for the fabric. A universal needle works for most light to medium fabrics, while a special jeans or jersey needle meets specific needs. Thread the machine following the diagram indicated to ensure balanced thread tension.

You can call on the Verotex experts to repair your sewing machine, whatever the issue.

Thread and Bobbin Tension Problems

Incorrect tension between the upper thread and bobbin thread causes loose stitches, loops, or puckering.

A tension imbalance shows as visible threads on one side of the fabric. This compromises the strength and appearance of the seams, requiring quick adjustment.

To adjust the tension, use the upper thread tension dial (between 3 and 5), then check the bobbin installation ensuring it spins freely without excessive resistance. Balanced tension is recognized by even stitches, without loops or visible thread on either side. Test by sewing a sample before starting your final project.

If your sewing machine is acting up, you can rent a high-performance machine from our online store.

Maintenance and Prevention of Stitch Problems

To avoid stitch problems, regular maintenance is essential. Frequently clean the bobbin compartment, feed dogs, and needle plate to remove dust. Knowing how to properly oil a sewing machine is crucial: apply a specific oil to moving parts after each use. Proper lubrication reduces wear and ensures smooth operation of the sewing machine.

|

Recommended Maintenance Schedule for Different Types of Sewing Machines |

|||

|

Type of machine |

Cleaning Frequency |

Areas to Lubricate |

Ratings |

|

Basic Mechanics |

Every 10 hours of use |

Needle, bobbin hook, feed dogs |

Use a soft brush and oil |

|

Multifunction electronics |

Every 5 hours of use |

Movement bearings, |

Check the manual for points of |

|

Overlock sewing machine |

After each project |

Feed dogs, cutting blade |

Clean thread lint after each session |

|

Industrial sewing machine |

Every 2-3 months |

All metal friction points |

Professional maintenance |

Store your sewing machine in a dry place, protected from dust. Prefer quality threads, such as those from the Schmetz brand, to reduce friction and breakage. Likewise, use new needles suited to the fabric, especially if you own a Juki sewing machine, known for its precision and specific requirements. These choices limit debris buildup and preserve internal mechanisms, ensuring even stitches and a long lifespan for your machine.

Stitch problems on a sewing machine often stem from a defective needle, improperly adjusted tension, or neglected maintenance. Act quickly by checking these elements to restore smooth sewing.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.