Table of contents:

Piped buttonholes are an essential feature of high-end jackets and coats. This type of buttonhole is made at the beginning of the construction, before assembling the collar and facing, to achieve a flawless and structured finish. In this article, we explain step by step how to successfully make a piped buttonhole with precision.

What materials and preparation are needed?

Before starting, it is essential to prepare the necessary elements:

- Fabric rectangles (in the same fabric or a contrasting fabric) to form the welts.

- Fusible interfacing to reinforce the buttonhole area.

Rectangle dimensions

- Length = Buttonhole width + 3 cm.

- Width = 4 to 6 cm, depending on the thickness of the fabric.

- Reinforcement: fuse the wrong side of the rectangles.

How to mark the buttonhole location?

- Marking the Buttonhole Location

Using the pattern, determine the exact width of the buttonhole and mark its position on the wrong side of the fabric with a washable pencil.

- Positioning Markers with Pins

Place two pins perpendicular to the ends of the buttonhole to mark its position on the wrong side.

- Reinforce the Area with Fusible Interfacing

Cut a rectangle of fusible interfacing (3 to 4 cm wide and slightly longer than the buttonhole). Attach it with an iron to the wrong side of the fabric.

- Hand Baste the Markings

To guide the sewing, make a hand basting following these codes:

- Blue thread: Corresponds to the width of the buttonhole.

- Red thread: Indicates the buttonhole slit.

- Place a Rectangle of Fabric

Take a rectangle of fabric and position it right sides together over the buttonhole area. Fold it in half lengthwise to find its center and align it with the red basting thread.

- Hold in Place

Secure the rectangle with pins or a basting stitch to prevent any movement during sewing.

How to sew and cut the opening?

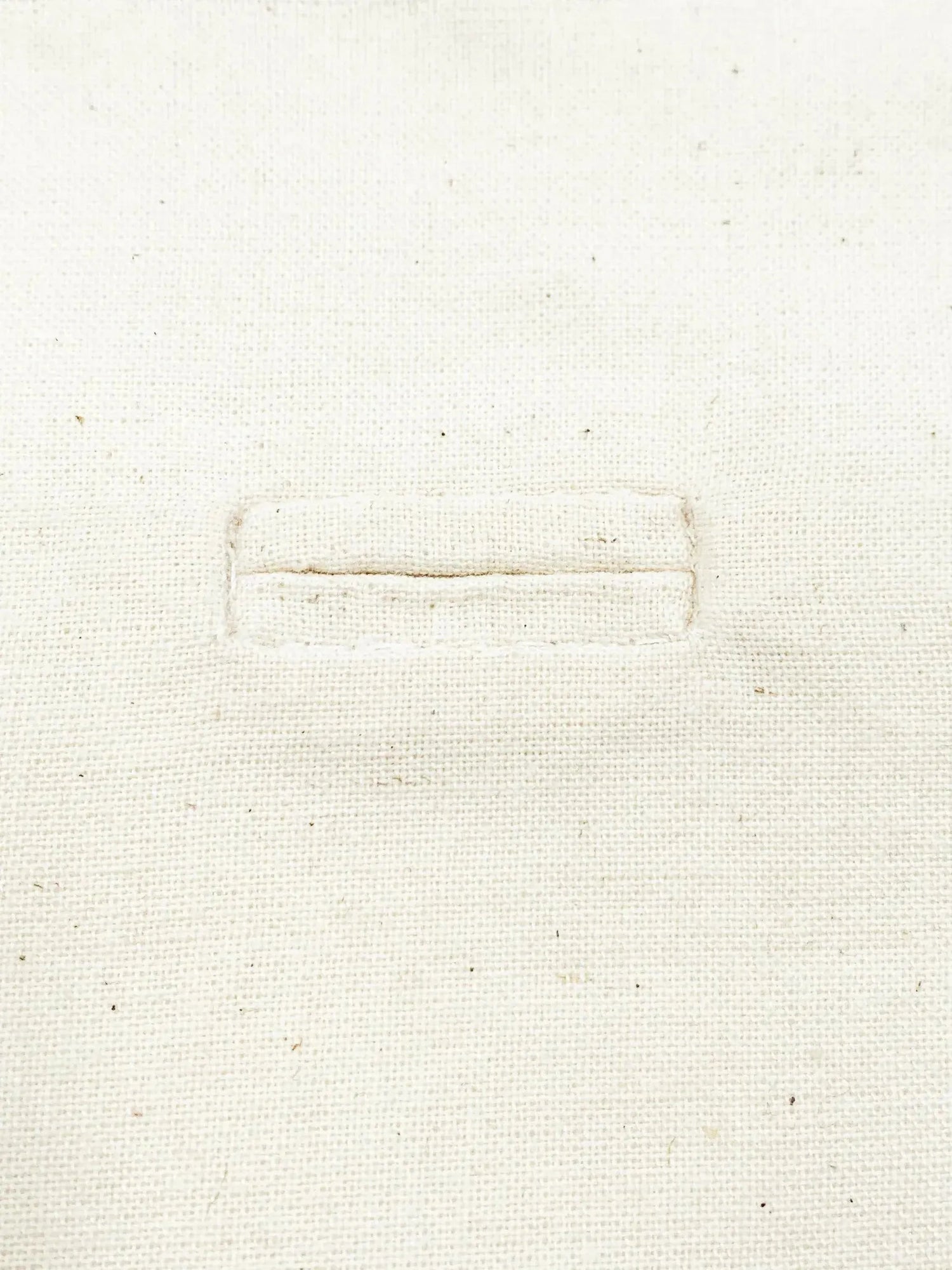

- Draw a Sewing Rectangle

On the wrong side of the fabric, draw a rectangle around the buttonhole:

- Vertical seams: are sewn on the markings (blue and red thread).

Tip: Start and finish with small stitches to reinforce the seam.

- Sew the Rectangle

Stitch along the line, taking care to mark the corners well.

- Cut the Buttonhole Opening

Using fine scissors, open the slit in the center of the sewn rectangle. Stop cutting 2 mm from the ends, then cut diagonally towards each corner forming small triangles.

- Turn the Fabric

Slide the fabric rectangle through the opening to bring it out on the wrong side of the project. Press carefully to flatten the edges well.

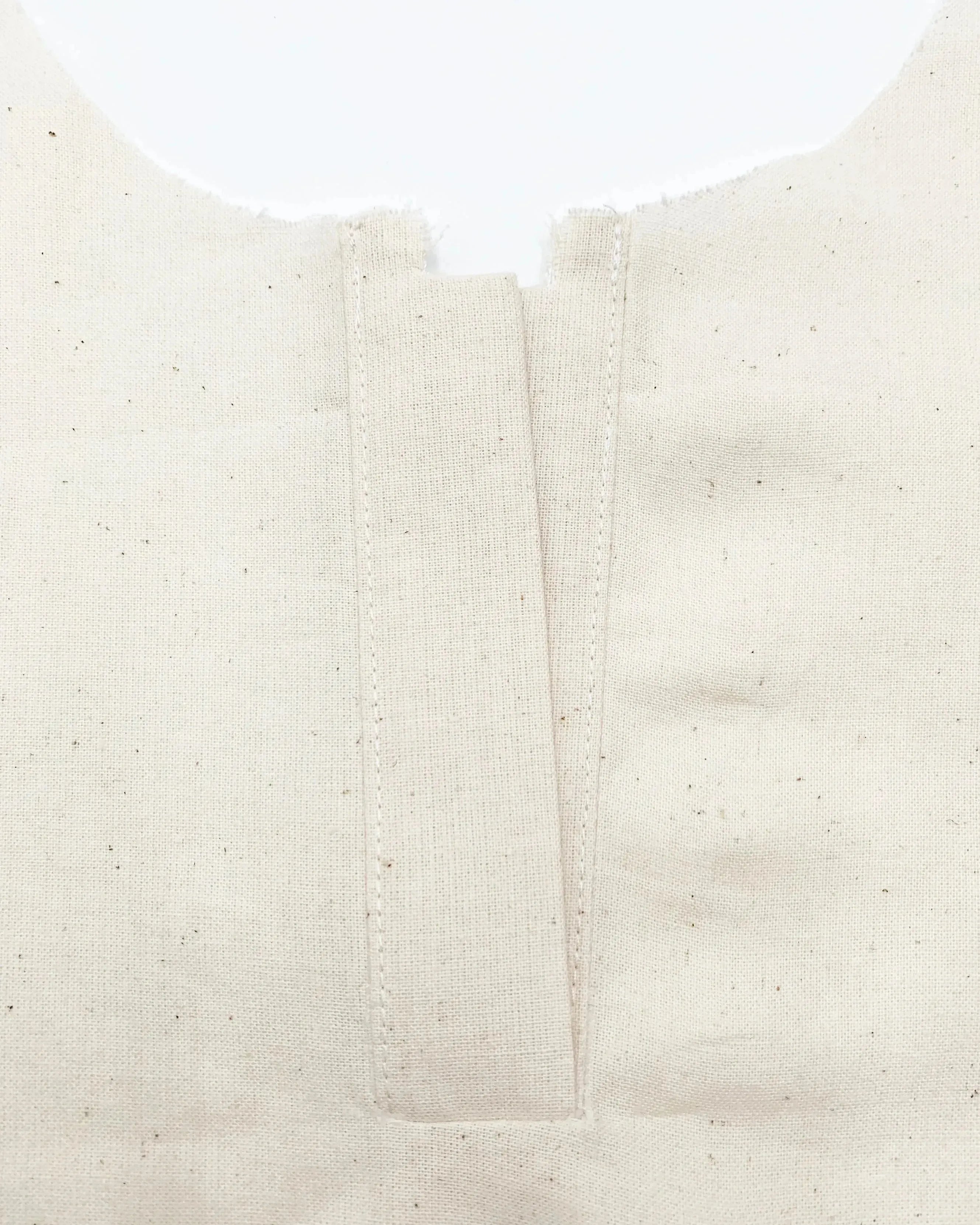

How to form Piping?

- Preform the Piping

Fold each fabric edge inward to form two even strips. Press to mark the folds well.

- Attach the Piping

Hold the piping in place with pins and a basting stitch to ensure a perfect fit.

- Buttonhole Finishing

Using a straight stitch with a length of 2, secure the piping and remove the basting threads. Press one last time to properly shape the buttonhole.

How to finish and ensure clean edges?

- Clear the Corners

On the wrong side of the fabric, carefully cut two small triangles at the ends of the buttonhole.

- Attach the Facing

If the buttonhole is integrated into a jacket or coat, the facing can be attached around it to hide the inner finishes. Stitch and press for a clean result.

Conclusion

By following these steps precisely, you will achieve an elegant and professional piped buttonhole, ideal for jackets, coats, or garments requiring a refined finish. This technique requires precision, but the result is worth it!

Also read:

How to sew a classic buttonhole?

Mistakes to avoid when creating buttonholes

Have you ever tried this technique? Share your feedback in the comments!

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.